What is RTLS?

Real-time location data that turns movement into business insight

Real-Time Location Systems (RTLS) capture where things are. RTLS software is not one technology. It is a family of solutions with different strengths. The right choice depends on what you track, where you track it, and how accurate or frequent the updates need to be.

RTLS software can combine UWB tracking software, BLE asset tracking, RFID tracking software, Wi-Fi positioning systems, and QR Code tracking systems. It is a practical GPS alternative indoors and supports asset tracking without GPS when satellite signals are unavailable.

Installing RTLS solutions typically involves selecting the right technology, deciding what areas to cover, deciding on the density of the tracking infrastructure, and configuring and calibrating the solution for the desired level of accuracy, the frequency of updates, and trading these decisions off against cost and battery life.

Why RTLS projects fail

High CapEx and long projects that miss expectations

What FORMATION needs from RTLS

Reliable zone-based intelligence

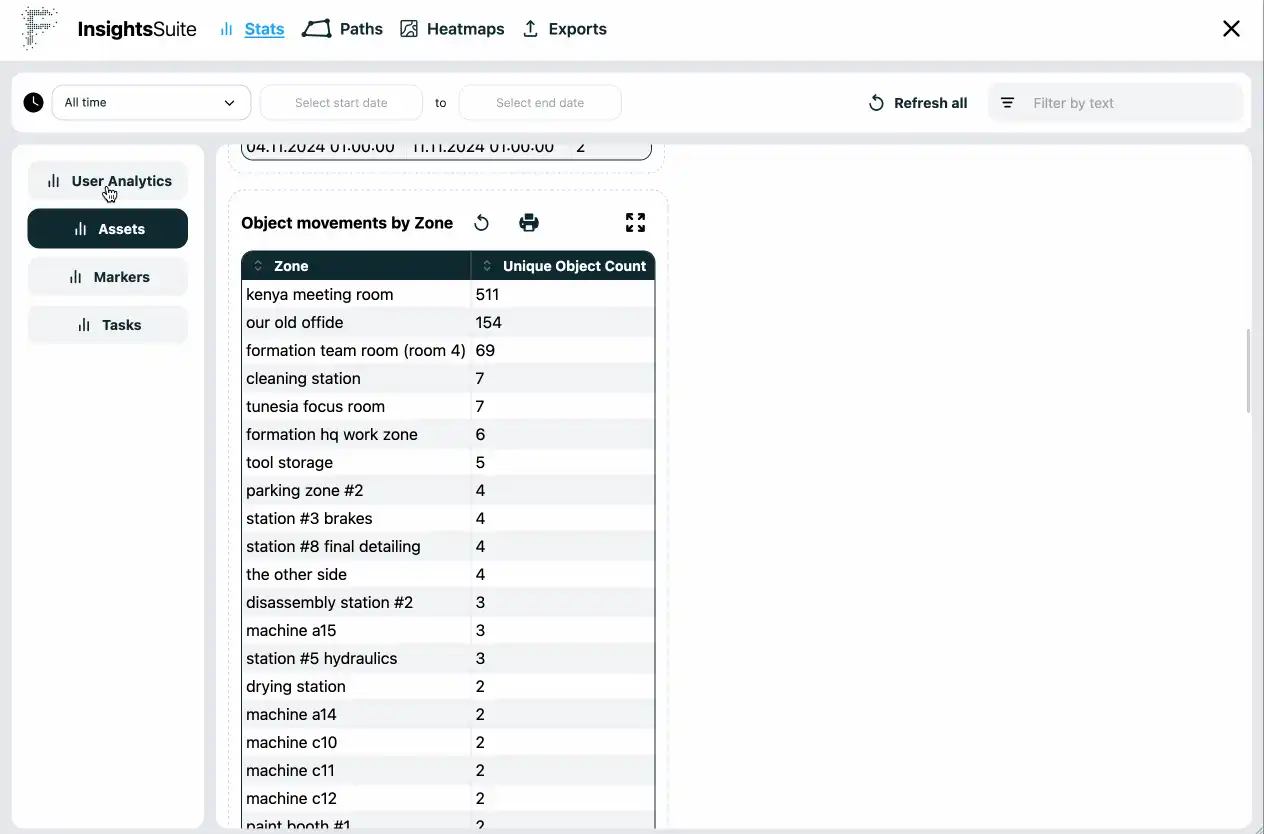

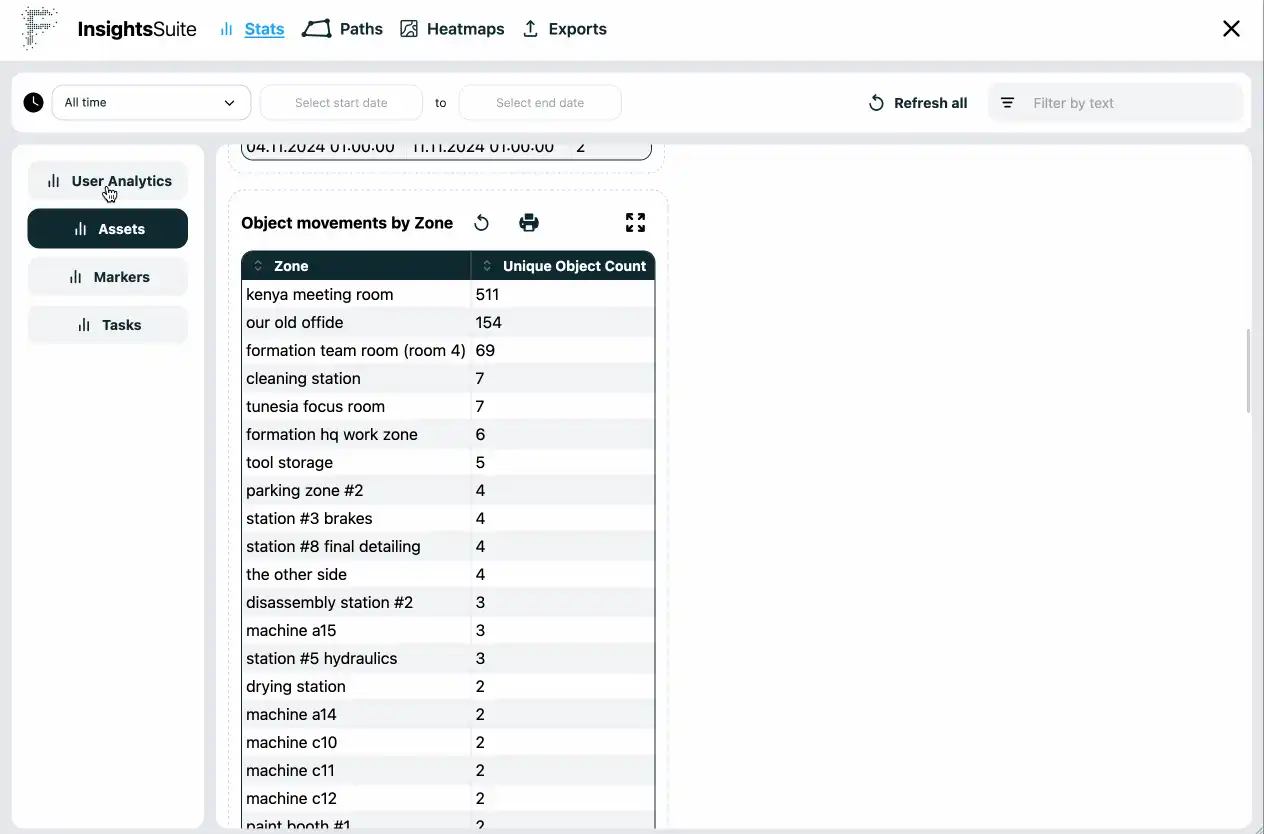

FORMATION is designed around operational decisions, not raw coordinates. In most industrial and logistics use cases, the critical question is not an exact position, but whether an asset is in the right place at the right time.

For this reason, FORMATION prioritizes robust zone entry and exit detection over absolute precision. A zone here can be a storage location like a room or shelf, a container or pallet, delivery or pickup points for logistics, or particular machines or work areas in your factory.

Open standards keep RTLS data easy to embed in existing software and services. FORMATION supports OMLOX and aligns RTLS with Asset Administration Shell (AAS) and Digital Product Passport (DPP) 4.0.

Accuracy requirements are driven by the size of your zones and the size of the things you are tracking.

- Zone entry / exit events: Detect when assets move into or out of defined areas such as halls, workstations, storage zones, docks, or safety areas.

- Consistency over precision: Reliable transitions matter more than centimeter-level accuracy for most workflows.

- Scalable coverage: Zones can span rooms, halls, campuses, or sites, and work across mixed technologies.

- Technology-agnostic inputs: UWB, BLE, RFID, GPS, and passive scans all contribute to the same zone logic in a hybrid RTLS solution with sensor fusion tracking.

FORMATION's phased RTLS approach

Match requirements, prove value, then scale

FORMATION works with best-in-class partners to match customer requirements to the right RTLS technology mix. We deliver a full stack solution from tags and infrastructure to maps, workflows, and analytics.

Our phased approach keeps risk low and value high:

- Start cheap with QR Code Tracking: Use QR Codes and the FORMATION App. It works out of the box and can be set up in days.

- Scope RTLS for the highest value areas: Roll out RTLS where it matters most, starting with the most critical assets and zones.

- Deepen with integrations: Trigger updates, tasks, and notifications in your existing systems as you scale.

- De-risk with OpEx: Use a flexible pay as you go model to align spend with rollout.

The core trade-offs

Battery life, anchors, accuracy, and frequency

- Battery life: Higher update frequency shortens battery life. Smaller tags also mean smaller batteries.

- Anchor density: Higher accuracy requires more anchors and tighter calibration. Increasing the density also lowers the distance to the location tags which means they need less energy to send updates.

- Location accuracy: Do you need room-level, rack-level, or centimeter-level precision? Do you need to know the altitude.

- Location frequency: Do you need a live path or just periodic updates? For example self driving vehicles in factories requite high frequency and highly accurate locations for real time decision making. For warehousing solutions the frequency is less important. And the accuracy depends on the size of the items you track. Some storage locations are large, others are smaller.

Cost drivers you should plan for

Hardware is only the beginning

- Anchors and readers: more accuracy usually means more devices and infrastructure. Some of this equipment might be battery operated and some of it might require networking and power.

- Site surveys and calibration: to get an accurate quote for an RTLS installation, this is always required.

- Service and maintenance: Battery replacements for anchors and tags. Replacement of faulty equipment. Dealing with accuracy issues in specific areas or adding more areas.

Power usage

A simple battery life model

Tag battery life is primarily driven by how often a tag transmits and how much energy each transmission consumes. Ignoring configuration details, average power usage can be described with the following model:

$$ P_{avg} \approx P_{idle} + f_{update} \cdot E_{update} $$Where P is power, f is update frequency, and E is the energy cost per update.

Battery life then follows approximately as:

$$ T_{life} \approx \frac{E_{battery}}{P_{avg}} $$This relationship explains most RTLS trade-offs: higher update rates and longer transmission ranges reduce battery life, while lower frequencies and denser infrastructure extend it. Battery life then follows directly:

Typical RTLS performance ranges

The ranges below reflect typical deployments. Actual performance varies by environment, tag configuration, and infrastructure quality.

| Technology | Typical battery life | Typical update frequency | Typical accuracy | Tag Cost | Infrastructure Cost |

|---|---|---|---|---|---|

| UWB | 6-24 months | 1-10 / second | 10-30 cm | High | High |

| BLE + AoA | 3-5 years | 1-4/minute | 1-3 m | Medium | Medium-High |

| BLE | 3-5 years | 1-4/minute | 3-5 m | Medium | Medium |

| GPS | 3-5 years | 0.2-1/minute | 10-30 m | Medium | Free |

| RFID | >5 years | When detected by scanner | Zone or gate level | Low | Scanners only |

RTLS tag types

Active, passive, and multi-technology tags

RTLS capabilities are defined not only by infrastructure, but by the tags themselves. Different tag types trade off accuracy, battery life, cost, and longevity. Many modern tags support multiple technologies in a single device, allowing one tag to operate across different environments and tracking modes.

Choosing the right tag strategy lets you concentrate high-performance tracking where it delivers value, while still maintaining broad, cost-effective coverage.

- Single-technology tags: Optimised for one method such as UWB, BLE, or RFID. Simple, cost-effective, and well suited for focused use cases.

- Multi-technology tags: Combine UWB, BLE, AoA, and/or RFID in one device. These adapt to available infrastructure, delivering high accuracy where needed and low-power tracking elsewhere.

- Passive identifiers: QR codes and barcodes require no battery or maintenance and scale to very large volumes.

Technology risk factors

Environmental and operational constraints

- Metal and liquids: Metal shelving, machinery, vehicles, and liquids absorb or reflect radio signals. This can degrade BLE, UWB, and RFID performance if not accounted for in design and calibration.

- Line of sight and occlusion: Walls, racks, stacked goods, and people can block or distort signals, especially in dense industrial environments.

- Multipath effects: Reflections from floors, ceilings, and machinery can introduce noise and false positions, particularly for radio-based systems.

- Motion and speed: Fast-moving assets require higher update frequencies and tighter calibration, increasing battery and infrastructure demands.

- Operational discipline: Systems that rely on manual scans or specific user behaviour introduce human risk and gaps in data quality.

Passive tracking beyond RTLS coverage

Track everything, anywhere

All tags can be combined with FORMATION QR Codes. This enables passive tracking outside areas covered by RTLS infrastructure, extending visibility beyond buildings, sites, and fixed installations.

Passive tracking leverages GPS/GNSS via mobile devices and scanners. It works anywhere in the world and complements active RTLS by filling coverage gaps without additional infrastructure.

Mix and Match

The more you track, the bigger the benefit

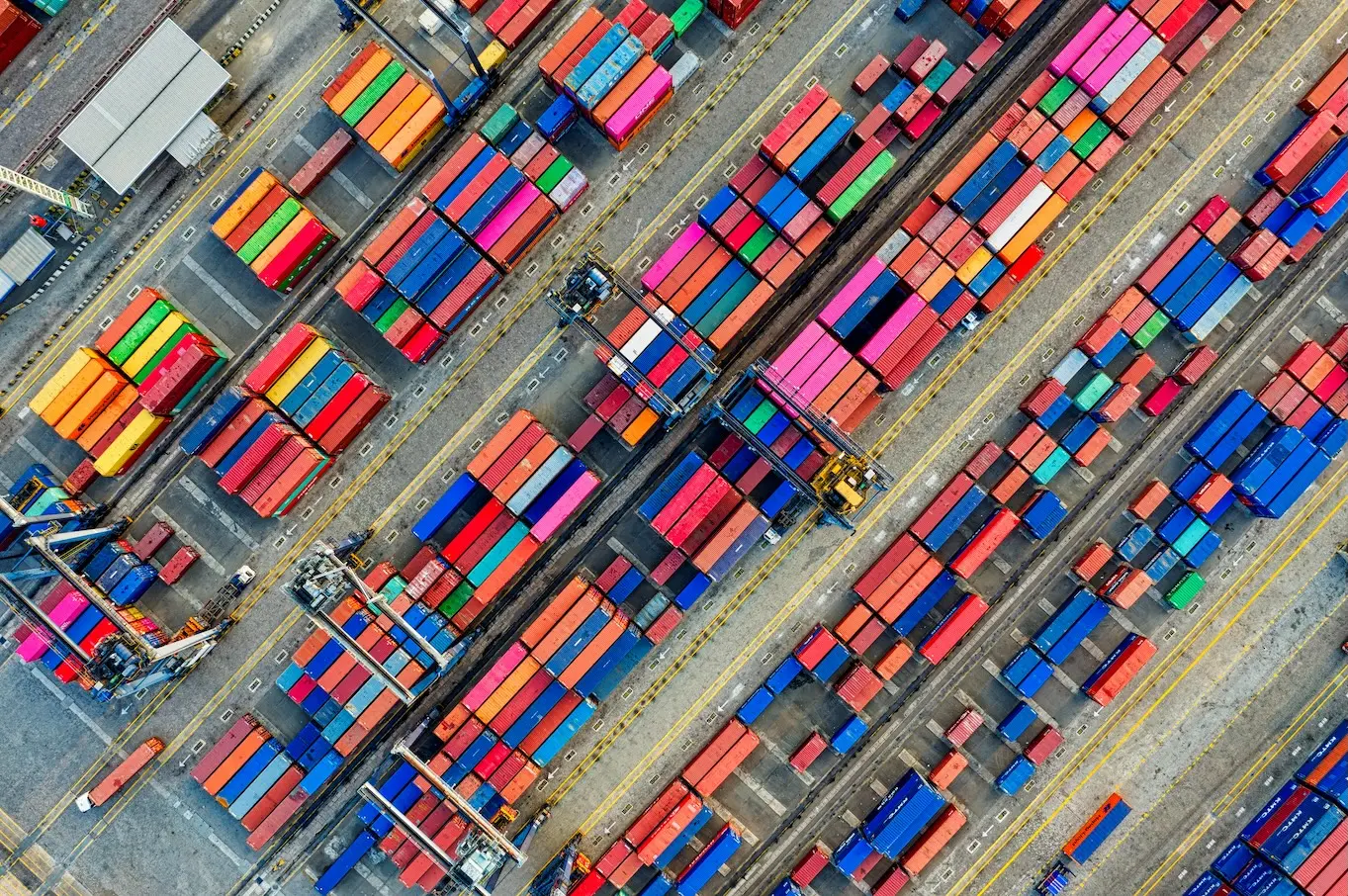

The best Tracking strategy is rarely a single technology. High-value assets benefit from high accuracy and frequent updates. High-volume assets benefit from low-cost, scalable methods that keep your overall coverage complete. Ideally your solution covers both.

And you should also think about where the solution works. Some technologies only work in speficic halls. But you might have a large campus. Or multiple sites. And what about the rest of your supply chain or when things are in transport?

FORMATION’s hybrid tracking helps you combine active RTLS based tracking with passive tracking so you can scale without losing visibility. Start where the value is highest and expand with confidence.